In addition to petroleum-based insulating oils, THIBIDI also provides FR3 Envirotemp insulating oil, which is a plant-based oil. This oil is environmentally friendly and has a high flash point, significantly reducing the risk of fire and explosion, thereby ensuring safety in residential areas. FR3 oil is used in transformers as per customer requirements.

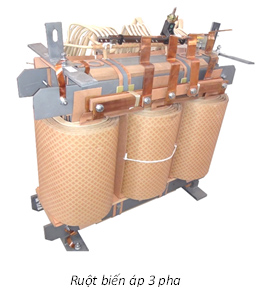

Core Assembly:

yokes are installed and securely clamped with bolts.

yokes are installed and securely clamped with bolts..jpg) Drying and Oil Filling:

Drying and Oil Filling:

In addition to petroleum-based insulating oils, THIBIDI also provides FR3 Envirotemp insulating oil, which is a plant-based oil. This environmentally friendly oil has a high flash point, significantly reducing the risk of fire and explosion, ensuring safety in residential areas. FR3 oil is used in transformers as per customer requirements.